Essential, reliable check weighing

An affordable check weigher is ideally suited to replace spot checks with 100% inline weight control. The easy-to-use system offers reliable performance for food and non-food applications in dry and wet environments.

Reliable Performance

Standardized, modular design with either an IP54 or IP65 rating. A variety of standardized mechanical and software options support individual needs.

Intuitive Operation

A robust 7″ color touchscreen offers intuitive operation in 30 languages. Machine messages are communicated as clear text.

Quick and Easy Installation

Pre-configured machine height, conveyor length, recipe memory, and weighing limits and tolerances support the system’s easy installation.

Product Description:

key features and functions of an automatic check weigher with rejector:

- Basic Weighing Functionality: Economic check weigher s typically focus on accurate weighing capabilities to ensure products meet predefined weight criteria.

- Simple User Interface: These check weigher s often have straightforward interfaces for ease of use, with minimal training required for operators.

- Speed and Throughput: While economic models may not offer the highest speeds or throughput compared to premium models, they still provide reasonable performance levels suitable for many production lines.

- Compact Design: Economic check weigher may have a more compact footprint, making them suitable for integration into smaller production spaces.

- Cost-Effective Maintenance: The design of economic check weigher s may prioritize easy maintenance and servicing to minimize downtime and keep operational costs low.

- Basic Data Reporting: While not as comprehensive as advanced models, economic check weigher s may still provide basic data reporting capabilities, such as weight statistics and production counts.

- Customizable Options: Some economic check weigher s may offer optional features or customizations to tailor the system to specific production needs without adding unnecessary complexity.

It’s essential for businesses to evaluate their specific requirements and budget constraints when selecting a check weigher to ensure they choose the most suitable option for their operations.

Top of Form

Bottom of Form

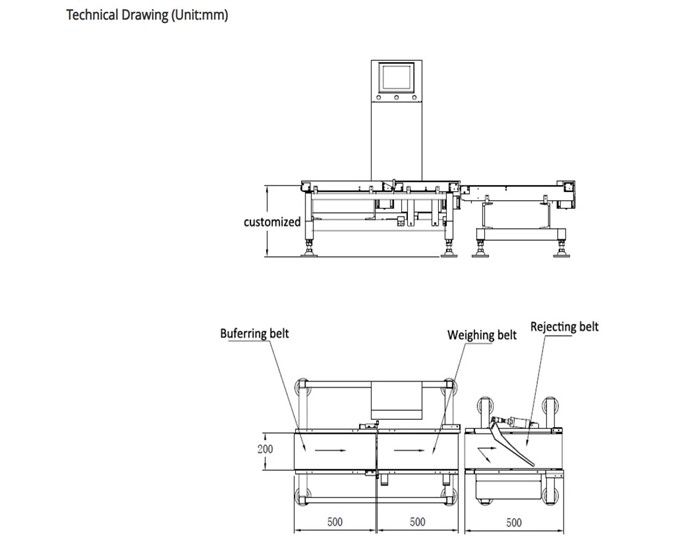

Technical Parameter for Automatic check weigher with rejector

| Model | DHCW-500*200 |

| Weighing product | Weight range (1g-5000g) |

| Max size: (300*150*250 mm L*W*H) | |

| Weighing capacity | 3000g |

| Minimum graduation | 0.01g |

| Weighing speed | 120 pcs/min |

| Weighing accuracy | ±1-3g |

| Weighing belt size | 500mm*200mm (L*W) |

| Weighing direction | From left to right (Facing the operation display) |

| Weighing sensor | Germany HBM |

| Control system | Dahang (Independent R & D) |

| Operation display | 8 inches touch screen |

| Weighing data output | USB port |

| Rejecting type | Flapper/pusher (with light alarming) |

| Products parameters | Can restore and recall 100 products |

| Belt conveyor | Food grade white color Belt |

| Language | English |

| Height of conveyor | 750+60mm (Customized) |

| Power supply | Single phase AC220V±10%, 50/60HZ |

| Construction | SUS304, polishing |

| Using environment | Normal |

| Package | With plastic film inside and professional export wooden case outside. |

| HS code | 84232010.00 |

Features

- 3 conveyors: Buffering belt, weighing belt and rejecting belt

- Strong stainless steel 304 structure

- Reliable and stable weighing control system

- High speed digital filter processing and automatic zero-tracking function

- Humanized operating system, easy to learn and operate, a variety of language versions available.

- Operation display: 8 Inches Color Touch Screen

- Product Storage: 100 kinds of product preset

- Weighing data output: USB port to download data into Excel.

- Rejecting system: Pusher, Lever/Flapper, Air Jet, Slide available for choice.